Install Waterstops

COMPANY How To Install Waterstops?

Concrete joints, where two or three sections of the concrete meet, are the weakest points easily being subjected to liquid leakage. So a number of waterstop products are designed to form a moisture barrier to deal with these issues.

Appropriate installation determines the performance of waterstops in water-proofing and reduces spalling and cracking of surrounding concrete. In order to provide convenience to our customers, the guidance of waterstop installation is list below:

Preparation:

1. Before installation, uncoil waterstops (especially for those waterstops have shape-memories) to let it resume straight shape - that makes waterstop easy to handle and fabricate.

2. Check the waterstop whether it has any defects or cracks. Replace the defective and unacceptable waterstops.

Installation:

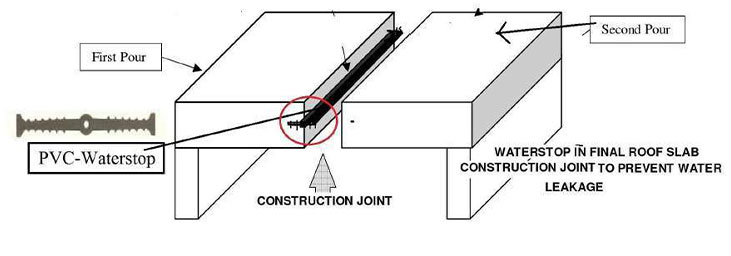

1. Place waterstops at the appropriate position. Make sure that about a half width of it is embedded in the concrete.

2. Contain about 1.5 times of clear coverage between the waterstop and surround reinforcing steel without any rock pockets and air voids.

3. Tie the waterstop to surrounding reinforcing steels by threading steel wire to metal eyelets, punched holes or hot rings of waterstops to fix the waterstop firmly. Meanwhile, make sure there is no displacement during fastening.

4. Pour the concrete and vibrate concrete nearby the joints (especially those under the waterstop) to enhance the contact with waterstops.

5. Clean debris and dirt of concrete surface after first pour.

6. Repeat the above methods for a second pour.

7. A half of waterstop is embedded in the concrete after the first concrete pour

Preventing Water Leakage through Construction Joints Introduction

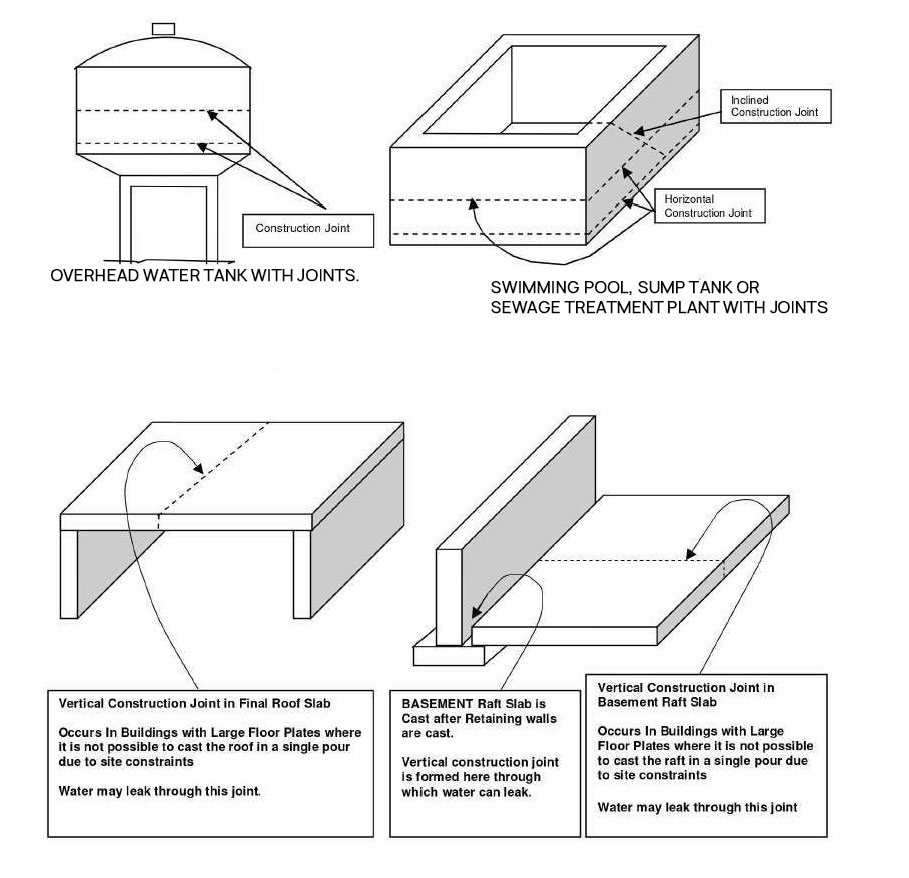

A typical problem in most Water Retaining Structures is the leakage of water through Construction and Cold Joints. A construction joint is formed when concrete is cast in different stages successively. These joints may be horizontal, vertical, inclined or curved depending on how the concrete is cast.

Structures which are prone to leak through their construction joints

| Water Tanks and Swimming Pools | Sump Tanks, Overhead Water Tanks |

| Basement Wall and Floor perimeter joint | Basement column and floor slab joint |

| Vertical joints in basement retaining walls | Sewage Treatment Plants |

| Potable water Reservoirs, Fish hatcheries | Septic tanks, Utility vaults |

| Raft Slabs cast in more than one pour | Final roof slabs cast in more than one pour |

| Pipe intrusions in concrete walls | Pedestrian and below grade tunnels |

| Precast structures such as box culverts | Butt joint between old roof and new roof |

| Raw Water tanks in Water Treatment Plants | Raw and Treated Water Tanks in Factories |

| Concrete lined storm water channels | Concrete lined Irrigation water channels |

Harmful effects of Leakage

In the case of water retaining structures like overhead water tanks and swimming pools, water leakage is unsightly and leads slowly to corrosion of the steel in the concrete. In addition, there is loss of water. In basements, rise in water level outside the structure allows water inside the basement and the basement may become unfit for use. Final roof slabs which have joints allow water to leak into the building which may destroy expensive interiors.

Why does water leak through construction joints?

Leakage occurs because

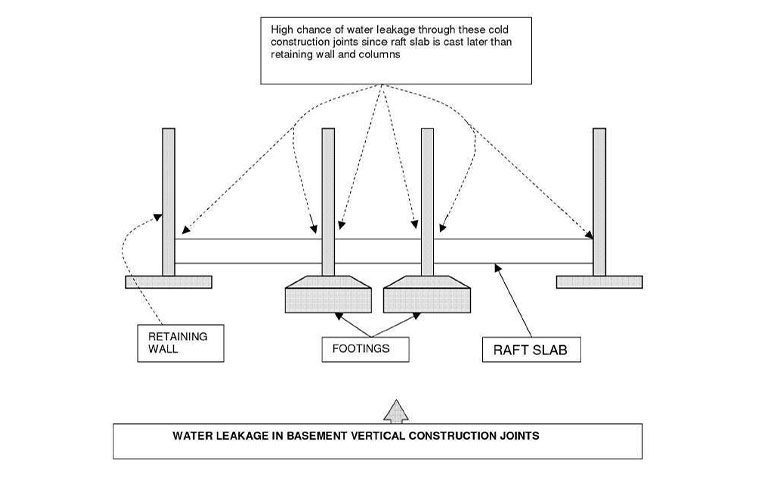

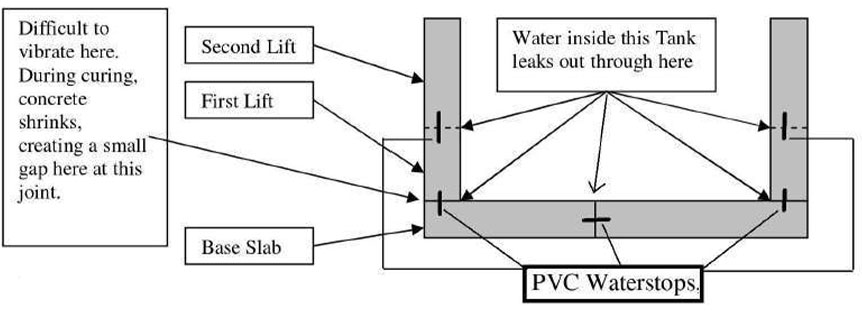

Generally, after the base slab is cast when the first lift of concrete is being placed for the wall of the water retaining structure, it is very difficult to vibrate at the bottom of the lift (floor and wall joint). Water then leaks through this open joint

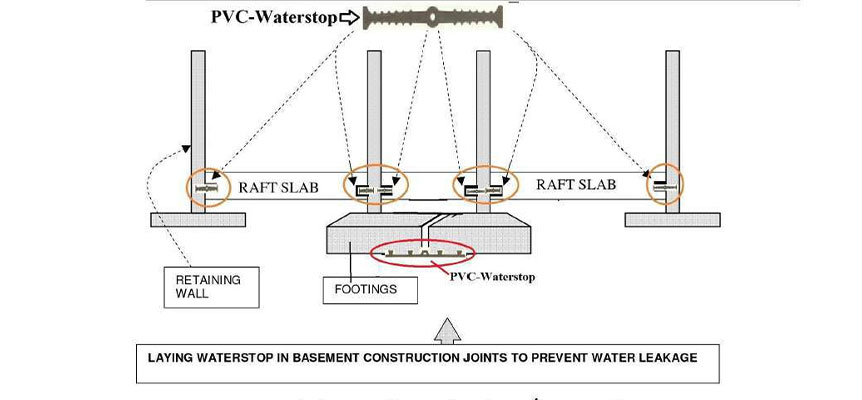

Traditionally, engineers have tried to solve the problem by using PVC Waterstops, The idea of introducing a PVC Waterston is to increase the path of the water flow and make the water lose its head before it exits from the construction joint.